Understand Our Custom Metal Manufacturing Core

Why Choose Custom Metal Manufacturing

In the highly competitive market, standard parts can no longer meet product requirements. However, custom metal manufacturing can overcome limitations and ensure that each component meets your needs.

Choosing a customized solution can simplify your supply chain. Achieve rapid prototyping and design iteration to help you bring your ideas to market efficiently and reliably.

Our Comprehensive Custom Metal Manufacturing Services

We focus on transforming your drawings into actual metal parts. Our core expertise lies in sheet metal processing, providing a complete solution from design optimization to mass production.

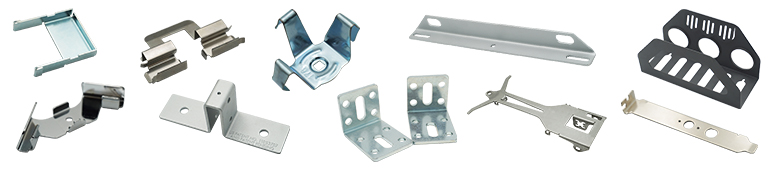

Precision stamping

We have 38 stamping machines (ranging from 80 to 400 tons) capable of high-efficiency, large-scale, precision stamping. Whether it’s a simple gasket or a structurally complex bracket, we can ensure dimensional consistency and contour accuracy, meeting your strict requirements for production efficiency and cost control.

Metal drawing and deep drawing

By using multiple hydraulic presses and mold technology, we are proficient in deep drawing and drawing forming. This process can form complex, seamless hollow-shell parts in a single piece, such as equipment casings, effectively avoiding potential welding-related defects and enhancing the structural strength and aesthetic appeal of the products.

High-precision laser cutting

Equipped with two sets of 6-kilowatt high-power fiber laser cutting machines, it can perform high-speed, precise cutting of various materials, including stainless steel, carbon steel, and aluminum.

The cut is smooth, free of burrs, and has a small heat-affected zone, making it suitable for cutting and sampling complex contours and delicate patterns, laying a solid foundation for precise bending and assembly.

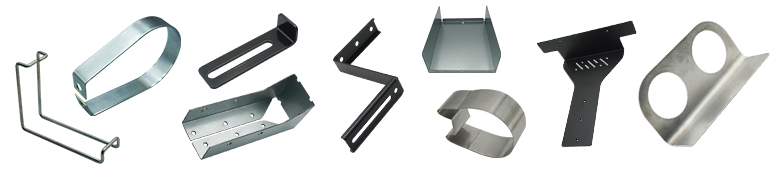

Precise bending and forming

Using advanced bending machines, various angles and complex shapes are bent accurately. It ensures accurate bending dimensions, effectively controls springback, and guarantees assembly consistency across batches.

Reliable welding connection

We have integrated multiple production lines, such as automatic spot welding and argon arc welding, and offer a variety of welding solutions. Ensure that the weld seam is firm and meets the specific requirements of different structural components for strength, sealing performance, or appearance.

—————————————————————————————————————————————————————————————-

In addition to the core sheet metal processing services mentioned above, we also offer CNC numerical control processing, metal casting, and comprehensive surface treatment processes.

Truly achieve one-stop, custom metal manufacturing that fully meets your project requirements.Here are some of our devices:

PS:Click here to learn about all of our devices

—————————————————————————————————————————————————————————————-

Why Choose Us as Your Partner?

We are committed to being your ideal partner for custom metal manufacturing. Help you turn the drawings into finished products.

Verified manufacturing capabilities

We were established in 1999 and have over 9,000 square meters of factory buildings certified by ISO 9001:2015 to ensure reliable production. The monthly production capacity exceeds 50,000 pieces.

To date, we have manufactured over 70,000 part types for more than 3,000 customers worldwide.

PS: Click here to view the parts we have made.

Engineering-led design optimization

We have 19 engineers with over 20 years of industry experience. They optimize your project in all aspects from the perspectives of cost, process, and materials.

A worry-free project journey

We offer free samples for you to verify the quality before mass production. Our professional service team will manage your project from quotation to delivery.In addition, we welcome customers to visit our factory in person and build trust through transparent cooperation.

By Cooperating with Us, You Will Get:

✅ 0.01mm precision guarantee

✅ Free sample available within 72 hours

✅ Random inspection service with authoritative quality inspection reports

✅ Provide a quick quote within 24 hours

✅ Business team follows up throughout

✅ Free project optimization

Now, click here and please contact us immediately!

+86 18892239158

+86 18892239158