Metal Fabrication

Metal Part Fabrication: One-Stop Custom Sheet Metal Fabrication

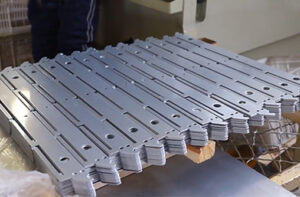

Metal fabrication is the process of shaping and assembling metal parts to create structures or products. There are several types, including cutting, welding, bending, stamping, and surface treatment. Xinjiuxinji covers all metalworking processes, and metal fabrication is widely used in construction, automobile, aerospace, and electronics industries. Typical applications include building frames, automotive parts, aircraft parts, and electronic housings.

Custom Metal Fabrication Factory: Global Supplier of Metal Products

Our capabilities range from precision metal fabrication of intricate parts to large-scale, straight forward projects, making us versatile in handling diverse customer needs. We take pride in delivering high-quality products at competitive prices, optimizing both performance and cost. Our advanced equipment, including 400 ton stamping machine, CNC machines, 6kw laser cutting machine, surface treatment production line and auto welding systems, ensures precision, efficiency, and high output.

As a metal fabrication supplier who has customized 70,000+ different metal parts, we attach great importance to customer service

✅ 0.01mm precision guarantee

✅ 100+ metal materials available

✅ Quote within 24 hours

✅ Samples available within 72 hours![]()

✅ ISO 9001 certification

✅ Free drawing optimization service

Your Trusted Partner in Metal Custom: The Xinjiuxinji Advantage

The aerospace and catering industries have exceptionally high standards and multiple challenges when it comes to metal processing. In aerospace projects, achieving extreme precision and ensuring material performance are crucial to meet mechanical and durability standards in complex environments. Similarly, the catering industry requires strict adherence to food-grade material standards and surface finish specifications.

We possess significant experience in customizing metal products for both the aerospace and catering sectors. This demonstrates our capability to manage the entire process, from developing high-precision components to producing high-sanitary items. As a result, we can offer highly reliable metal solutions tailored to meet the needs of customers in various industries.

✅ Technical guarantee: the most advanced equipment within 5 years, six engineers with 25 years of experience

✅Cost optimization: Free material selection and process solution cost reduction suggestions

✅Quick response: Provide quotation within 24 hours, and deliver urgent orders within 72 hours

✅Capacity guarantee: Factory area of 8,000 square meters, view factory resources

—————————————

Types Of Metal Fabrication: Unique Benefits and Applications

The most commonly used processing technologies for metal products in most fields are laser cutting and metal stamping, both of which involve sheet metal fabrication. Through these two steps, the final prototype of the product can generally be obtained. Different project requirements, such as quantity, material, and precision requirements, make us choose different processing methods.

| Stamping | A die presses shapes or patterns into metal sheets. |

| This process is fast and efficient, making it ideal for mass-producing parts like brackets, panels, and hardware. | |

| Cutting | Using lasers, waterjets, or plasma to cut metal into desired shapes precisely. |

| Ideal for intricate designs in automotive, electronics, and construction due to its accuracy and efficiency. | |

| Bending | Metal is bent into specific shapes using press brakes or rollers. |

| Machining | CNC machines precisely cut and shape metal, making them perfect for creating complex, high-precision components |

| Casting | Molten metal is poured into molds to create specific shapes. |

| Punching | Metal is pierced with a punch and die to create holes or cutouts. |

| Surface Treatment | Processes such as anodizing, powder coating, or electroplating are used to enhance surface durability, appearance, and corrosion resistance. |

These metalworking processes are essential for various industries, including aerospace, automotive, construction, electronics, and manufacturing, addressing both functional and aesthetic requirements.

Xinjiuxinji Has Rich Experience In Processing Different Materials

We have extensive experience in customizing products made from various materials, including stainless steel sheet metal fabrication, aluminum product fabrication, and iron fabrication. According to the use and performance requirements of the product, we choose to manufacture corresponding products through metal fabrication, such as metal enclosure fabrication, metal box fabrication, and metal frames.

- Stainless steel fabrication

- Iron fabrication

- Aluminum casting part

- Brass-part

- Stainless steel deep stamping

- Steel-part

- Various-metal-parts-assembly

| Steel | |

| Carbon Steel | A36, 1018, 1045, 1020 |

| Stainless Steel | 304, 316, 316L, 430, 410 |

| Tool Steel | D2, A2, O1, S7, H13 |

| Alloy Steel | 4140, 4340, 8620 |

| Aluminum | |

| 1000 Series | 1100 |

| 2000 Series | 2024 |

| 3000 Series | 3003 |

| 5000 Series | 5052, 5083, 5754 |

| 6000 Series | 6061, 6063 |

| 7000 Series | 7075 |

| Copper | C110 (Electrolytic Tough Pitch Copper), C101 (Oxygen-Free Copper), C182 (Chromium Copper), C220 (Commercial Bronze) |

| Brass | C360 (Free-Cutting Brass), C464 (Naval Brass), C260 (Cartridge Brass) |

| Titanium | Grade 1 (Commercially Pure Titanium), Grade 2 (Commercially Pure), Grade 5 (Ti-6Al-4V) |

| Nickel Alloys | Inconel: 600, 625, 718 Monel: 400, K500 Hastelloy: C22, C276 |

| Magnesium | AZ31B, AZ91D, ZK60A |

| Zinc | Zamak 3, Zamak 5, Zinc 710 |

| Lead | Pure Lead Lead Alloys: Antimonial Lead, Calcium Lead |

| Bronze | C932 (Bearing Bronze), C954 (Aluminum Bronze), C863 (Manganese Bronze) |

These metals cover a wide range of industrial needs, offering durability, resistance, and machinability for various applications.

Ready to Get Started? Contact Xinjiuxinji for Your Metal Custom Needs

Xinjiuxinji is good at metal fabrication. Many metal products, made from various materials such as stainless steel and aluminum, are processed through sheet metal stamping, laser cutting, and other metal fabrication methods in sheet metal fabrication. We strictly control the quality and precision of products, and we will definitely let you get the most satisfactory product under the best solution.

+86 18892239158

+86 18892239158