One-Stop Manufacturing of Multi-Material Parts

In industrial manufacturing and innovative design, selecting metal materials is vital. Stainless steel has become the first choice for many projects due to its corrosion resistance, strength, and aesthetic appeal.

As a professional metal customization service provider, our core competence is precisely reflected in the precise stainless steel manufacturing, and we are committed to transforming customer blueprints into reliable, durable products.

From 1999 to 9,000 ㎡: Our Manufacturing Foundation

Since its establishment in 1999, we have been deeply engaged in the field of metal custom manufacturing. At present, we have grown into a modern manufacturing base covering over 9,000 square meters and have obtained ISO 9001:2015 quality management system certification.

We have a team of over 120 people, including 19 engineers with more than 20 years of experience. This lays a solid foundation for us to provide outstanding stainless steel manufacturing services. In addition, we also offer materials such as carbon steel, aluminum alloy, brass, and copper alloy.

Cornerstone of Full-Process Manufacturing: Advanced Equipment

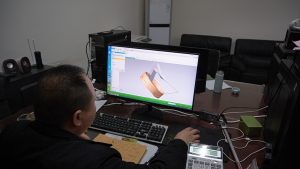

Our manufacturing capacity relies on a comprehensive list of advanced equipment.

Precise cutting from 6-kilowatt laser, to multiple five-axis CNC machining centers for complex three-dimensional processing, and then to automatic welding and various surface treatment production lines, we have achieved full-process control over metals such as stainless steel.

PS:Click here to learn about all of our devices

Multi-Material Manufacturing: From Stainless Steel to Brass

The over 70,000 parts cases we have accumulated are a direct manifestation of our strength. From the welded stainless steel chassis to the precisely machined five-axis CNC aluminum alloy components, and then to the surface-treated brass decorative parts .

PS: Click here to view the parts we have made.

Every part is the most intuitive answer that reflects our full-process capabilities.

Industry Solutions: Our Customized Cases

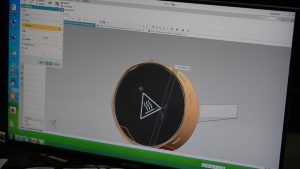

One of the outdoor product manufacturers we serve needs to customize a stainless steel windproof, energy-saving, and fire-retardant hood.

Core Challenge

- The structure of the tangent surface is complex

- The assembly accuracy should be controlled within 0.02mm

The two are directly related to the product’s final windproof performance and service life.

Our Solution

To address these challenges, our team of engineers offers free design optimization services. By improving the welding path and edge-curling process, the problem of complex forming was solved, significantly enhancing the product’s structural strength and air tightness.

Relying on our full internal production capacity, from laser cutting to automatic welding, we have eliminated the cycle uncertainty associated with external collaboration. Ultimately, a shorter delivery cycle than planned initially was achieved.

Quality and Delivery Assurance

✅ 0.01mm precision guarantee

✅ Samples are available within 72 hours

✅ Promises a quick quote within 24 hours

✅ Random inspection service with authoritative quality inspection reports

Why Choose Us: The Common Trust of Global Customers

We have provided customized services to over 3,000 enterprises across more than 100 countries worldwide. We promise to offer free sample services so you can verify the quality of our stainless steel manufacturing with zero risk.The picture below shows our sample display cabinet.

We offer one-stop services from design to after-sales. An experienced team of engineers will provide free design optimization at the early stage of the project, covering drawings, materials, processes, and surface treatments.

Our professional business team will follow up throughout the process to ensure a seamless connection from demand confirmation to production monitoring to after-sales feedback, eliminating your worries.

Welcome to contact us at any time. With one of your drawings, we can start our following manufacturing case.

+86 18892239158

+86 18892239158