Need a Reliable Sheet Metal Fabrication Partner?

Why Choose One-stop Metal Parts Processing?

Dual guarantee of efficiency and quality

Integrate the entire manufacturing process and greatly simplify the communication links. Our internal collaboration ensures seamless connection at every step from production to delivery, guaranteeing consistent quality and timely delivery.

In-depth optimization of cost and performance

One-stop service can avoid the additional costs and potential risks brought by subcontracting. Our engineers can conduct analysis from the design source, optimize materials and processes, and enhance the performance of parts while controlling costs.

—————————————————————————————————————————————————————————————-

Our Core Processing Technology

Our core: Comprehensive sheet metal fabrication services

As a professional metal parts customization service provider, we offer a complete sheet metal fabrication capability covering blanking, forming, and joining, which are the core processes for manufacturing various sheet metal structural components.

1.Precision blanking: Laser cutting

Using a 6-kilowatt laser cutting device, high-speed, high-precision cutting of complex graphics is achieved, yielding smooth cross-sections and high-quality billets for subsequent bending and welding.

2. High-efficiency forming: Stamping and stretching

With 38 stamping machines ranging from 80 to 400 tons, punching and forming can be efficiently completed. For parts that require deep drawing, we have a mature deep-drawing process.

3. Precise shaping: CNC bending

Using advanced CNC bending machines, the bending Angle and size are precisely controlled to ensure accurate structures and smooth assembly of products such as chassis shells and metal brackets.

4. Firm connection: Multiple welding processes

We offer:

- Argon arc welding (TIG)

- Gas shielded welding (MIG/MAG)

- Resistance spot welding

- Laser welding

- Manual arc welding

A variety of welding processes, including these, are available to meet the connection requirements of different materials, thicknesses, and strengths.

Other processing and service extensions

In addition to core sheet metal fabrication, we can also offer supplementary processes, including CNC precision machining and metal casting.

Meanwhile, we have comprehensive surface treatment capabilities, including powder coating/painting, electroplating, anodizing, passivation, and screen printing, which impart corrosion and wear resistance, as well as a beautiful appearance, to parts.

PS:Click here to learn about all of our devices

—————————————————————————————————————————————————————————————-

Which Metal Materials Can We Process?

We have rich experience in handling a variety of metal materials, including but not limited to:

- Stainless steel (such as 304, 316)

- Carbon steel (cold-rolled and hot-rolled plates)

- Aluminum alloys (such as 5052, 6061)

- Copper and copper alloys (such as brass)

- Galvanized steel sheet

Our team can offer you professional material selection recommendations based on the strength, appearance, and budget requirements of the parts, ensuring you get the best cost-performance.

—————————————————————————————————————————————————————————————-

Why Choose Us as Your Sheet Metal Processing Partner?

Strong manufacturing capabilities and rich experience

We were established in 1999 and have a modern workshop of over 9,000 square meters, and have passed the ISO 9001:2015 certification.

With over 20 years of industry experience, we have customized more than 70,000 types of parts for over 3,000 enterprises across more than 100 countries worldwide. To date, our monthly production capacity has exceeded 50,000 pieces.

Industry-leading equipment cluster

The core sheet metal processing equipment includes 38 sets of 80-400-ton stamping machines, 2 sets of 6-kilowatt high-power laser cutting machines, and multiple sets of CNC bending centers.

In addition, two five-axis machining centers, a complete welding production line, two surface treatment lines, and two coordinate measuring machines (CMMs) ensure our one-stop service.

PS:Click here to learn about all of our devices

Free value-added services from the expert team

Among our team of over 120 people, 19 engineers have more than 20 years of experience. We offer you free one-stop project design and optimization services.

From drawings, materials, and processes to surface treatment, we help your design be easier to manufacture, perform better, and be more cost-effective. Give your project an edge from the very beginning.

Customer-centered full-process service

From the in-depth connection of pre-sale demands to the transparent tracking of production progress during the sale, and then to the rapid response after the sale, our professional business team ensures that you have no worries at every stage.

We sincerely invite customers to visit our factory in person and witness our production and management firsthand. Meanwhile, we offer free sample services, allowing you to personally verify the quality and craftsmanship, making your cooperation more reassuring.

—————————————————————————————————————————————————————————————-

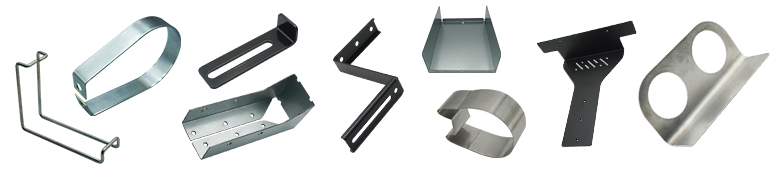

The following are some of the parts cases we have done.

—————————————————————————————————————————————————————————————-

Now, click here and please contact us immediately!

+86 18892239158

+86 18892239158