How We Fulfill Your Metal Bracket Customization?

Metal brackets, as load-bearing and fixing structures, are crucial to the stability and service life of terminal products. We have over 20 years of experience in manufacturing metal parts and specialize in providing full-process services for customizing metal brackets.

Whether it is standard specifications or special designs, we can flexibly choose from a variety of metals, including but not limited to:

✅ stainless steel

✅ cold-rolled steel

✅ aluminium alloy

✅ carbon steel

✅ brass alloy

In addition, we offer sheet metal processing, CNC precision processing, metal casting, and various surface treatments, supplemented by free design optimization.

—————————————————————————————————————————————————————————————————————–

Metal Bracket Case Display: From Simple to Complex

The following are representative projects we recently completed, demonstrate how we can transform customers’ ideas for metal bracket customization into reliable products.

Project Case One: Installation Bracket for Small Equipment

The customer requires a lightweight, compact installation bracket for mounting small sensor devices that is aesthetically consistent with the overall design of modern equipment.

The plan we proposed

- It is made of 6061 aluminum alloy and formed through precise laser cutting and CNC bending to ensure lightweight, high-precision performance.

- It features a long installation hole, which makes fine-tuning the installation position on site easier.

- It uses black powder coating, offering a uniform matte finish that is both beautiful and wear- and corrosion-resistant.

The achievements made

The bracket is approximately 130 millimeters long and 65 millimeters wide. It is lightweight and features a robust surface coating. Both in terms of appearance and functionality, it has received high praise, and subsequent customers have placed multiple repeat orders.

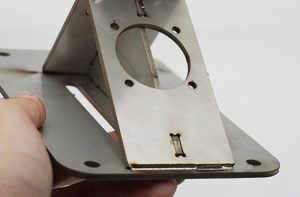

Project Case Two: Structural Installation Brackets

The customer requires a 304 stainless steel bracket for equipment in a clean room, which should be non-magnetic, corrosion-resistant, and screw columns should be welded at specific positions to simplify the final assembly process.

The plan we proposed

- It is made of 304 stainless steel, meeting the stringent requirements of non-magnetism and high corrosion resistance.

- By combining laser cutting and precise bending, the formation and connection of the support’s main body and the screw column are completed in a single step.

- It features a brushed finish that retains stainless steel’s original color while imparting a fine texture, making it easy to clean and maintain.

The achievements made

The supporting structure is firm, and the brushed surface has a high-end texture. Precise positioning and hole opening have enhanced the efficiency of subsequent assembly for customers. It fully complies with the customer’s usage standards.

Project Case Three: Foldable Load-bearing Support

The customer wants to develop a foldable retail display stand. It is required to have a load-bearing capacity of 20kg, be easy to store, and have a wear-resistant surface coating.

The plan we proposed

- It uses high-strength galvanized steel with a thickness of 2-3mm as the base material. It achieves smooth folding through a precisely designed hinge structure.

- Optimize the design of the reinforcing ribs to ensure the load-bearing stability after unfolding.

- By applying the electrophoretic whitening process, it features excellent rust prevention, wear resistance and chemical corrosion resistance.

The achievements made

The support structure is stable, and the load-bearing test far exceeded expectations. The surface is both beautiful and easy to maintain. The folding function has facilitated logistics, transportation, and warehousing, and has been successfully applied to multiple chain retail projects.

Project Case Four: Foldable Equipment Installation Bracket

The customer requires a 304 stainless steel bracket for fixing testing instruments. It is necessary that, under the premise of ensuring strength and hygiene safety, it can be quickly deployed, fixed, and stored to save space.

The plan we proposed

- The entire structure is made of 304 stainless steel to ensure excellent strength and complete biocompatibility.

- Weld the stressed parts to improve the support’s load-bearing capacity.

- It uses a stainless steel passivation process to enhance anti-rust performance while retaining the metal’s original color and texture.

The achievements made

The stainless steel material and surface treatment fully meet the customer’s requirements for the product. The welded bracket has high strength and stability. It ultimately won high recognition from end users and was widely applied in detection instruments.

——————————————————————————————————————————————————————————————————

Why Choose Us for Custom Metal Brackets?

Experience and Scale

Since its establishment in 1999, it has over 9,000 square meters of modern workshops and ISO 9001:2015 certification. The monthly production capacity exceeds 50,000 pieces, enabling large-volume delivery.

Full-process Service

- Pre-sale: In-depth communication to accurately understand your needs and application scenarios.

- During sales: Monitor production progress throughout the process, report regularly, and control delivery dates.

- After-sales service: Follow up on customer feedback, resolve issues quickly, and eliminate customer concerns.

Expert Team Support

19 engineers with over 20 years of experience offer free one-stop design optimization, covering everything from drawings and material selection to processes and surface treatment, helping you reduce costs and increase efficiency.

Advanced Equipment Cluster

From 38 stamping and laser cutting machines to five-axis CNC machining centers, automatic welding lines, and a complete set of surface treatment equipment, we offer full-process capabilities and can customize complex metals.Here is some of our equipment:

PS:Click here to learn about all of our devices

Quality Assurance

Equipped with two coordinate measuring machines (CMM) and other inspection devices, we offer batch spot checks and issue quality inspection reports as per your requirements. We strictly control every link from raw materials to finished products.

Open Inspection

We welcome you to visit our workshop at any time. You can directly witness the entire process, from cutting and forming to welding and surface treatment.

Global Service Verification

In addition,we also take on custom orders for other metal parts, including metal pallets, hardware tools, and metal boxes. At present, we have customized over 70,000 types of parts for more than 3,000 enterprises in over 100 countries.

PS: Click here to view the parts we have made.

—————————————————————————————————————————————————————————————-

If you are seeking a reliable, professional, and highly cooperative manufacturing partner, whether for a simple bracket or a complex structural component, we will provide you with the most competitive metal bracket customization solution.

Click here to send an inquiry and we will reply to you within 12 hours!!

—————————————————————————————————————————————————————————————-

Our Quality and Delivery Assurance

✅ 0.01mm precision guarantee

✅ Samples are available within 72 hours

✅ Promises a quick quote within 24 hours

✅ Random inspection service with authoritative quality inspection reports

+86 18892239158

+86 18892239158